Pompo ea seretse ea ZNQ e ka tlas'a metsi

Kenyelletso e khuts'oane: pompo ea seretse ea ZNQ ke mochini oa hydraulic o sebetsang ka kopanelo le enjene le pompo ho qoela bohareng.Pompo e na le ts'ebetso e phahameng, e hanyetsanang le abrasion e matla, e susumetsang e hahelletsoeng ka hare, mohlala o feletseng, 'me e na le mekhoa e mecha ea ho etsa li-hydraulic le moralo oa moralo.Anti-abrasion high chromium wear-resistant alloy casting ke sesebelisoa se loketseng bakeng sa ho pompa seretse, ho hula, ho hula lehlabathe le ho ntša slag.E ka sebelisoa ho pharaletseng lik'hemik'hale, merafo, matla a mocheso, metallurgy, meriana, borokho le qubu ea boenjiniere ba motheo, mashala, ts'ireletso ea tikoloho le liindasteri tse ling ho tsamaisa slurry e nang le likaroloana tse thata tse thata.Joalo ka limela tsa tšepe le tšepe tse pompang likala tsa iron oxide, ho hloekisoa ha letamo la fektheri, ho hlatsoa lehlabathe la khauta, ho fetisoa ha tšepe ea tšepe, ho fetisoa ha molora oa semela, ho tlosoe molora oa hydraulic lifemeng tsa motlakase o futhumatsang, seretse sa mashala le phetiso e boima ea media ka mashala. ho hlatsoa limela, ho chesoa ha likotopo tsa noka, ho chesoa le ho chesoa ha Noka, boenjiniere ba motheo oa qubu, joalo-joalo.

Tlhaloso ea mohlala:

100 ZNQ (R)(X)100-28-15(L)

100 - bophara bo tloaelehileng ba boema-kepe ba ho ntša pompo (mm)

ZNQ - pompo ea seretse e ka tlas'a metsi

(R) -Ho hanyetsa mocheso o phahameng

(X) -Tšepe e sa hloekang

100 - sekhahla sa phallo e lekantsoeng (m3/h)

28 -hlooho e lekantsoeng (m)

15 - motlakase o lekantsoeng ka matla (Kw)

L) -sekoahelo se pholileng

Lintlha tsa tekheniki

Ho ea ka bophara, ho na le 2, 3, 4, 6, 8, 10, 12, 14 inch, matla: 3KW-132KW, re ka boela ra hlahisa ho ea ka tlhokahalo ea bareki.

Molao-motheo oa ho sebetsa

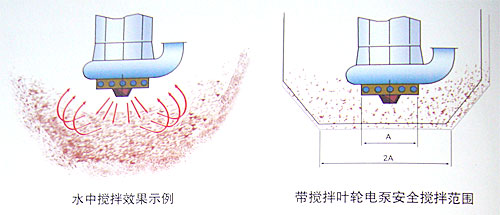

Ho phaella ho mokelikeli o ka sehloohong, tlase e boetse e na le mochine o susumetsang.Mochine oa motlakase o khanna mochine oa pompo ea metsi le mochine o susumetsang hore o potolohe ka lebelo le phahameng ho fetisetsa matla sebakeng sa slurry medium, e le hore sediment, sediment le slurry li tsosoe ka ho lekana, 'me pompo ha e be teng. sesebelisoa se thusang, phetisetso e phahameng ea concentration e finyelloa.

Ho phaella moo, bakeng sa maemo a khethehileng moo sediment e kopantsoeng kapa lehlabathe le le thata, 'me le ke ke la phethoa feela ka pompo ea pompo le ho itšehla thajana, li-agitators tse mahlakore a mabeli le a mangata (reamers) li ka ekeletsoa ho lokolla sediment le. eketsa mahloriso a ho ntša.Ho fihlella ho hula ka ho iketsa hinge.E boetse e thibela matla a mangata ho koala pompo, ho lumella lintho tse tiileng le metsi hore li kopane ka ho feletseng bakeng sa ho sebetsana ha bonolo.

Thepa e phallang haholo: tlhophiso e tloaelehileng e phahameng ea chromium e sa sebetsaneng le alloy (cr26).

Tse ling tse kang li-alloys tse tloaelehileng tse manganga, tšepe e tloaelehileng, tšepe e entsoeng ka tšepe, 304, 316, le 316L tšepe e sa jeleng paate, le tšepe e sa hloekang ea duplex li ka etsoa ho latela maemo a fapaneng a ho sebetsa le litlhoko tsa bareki.

Litlhaku tsa lihlahisoa:

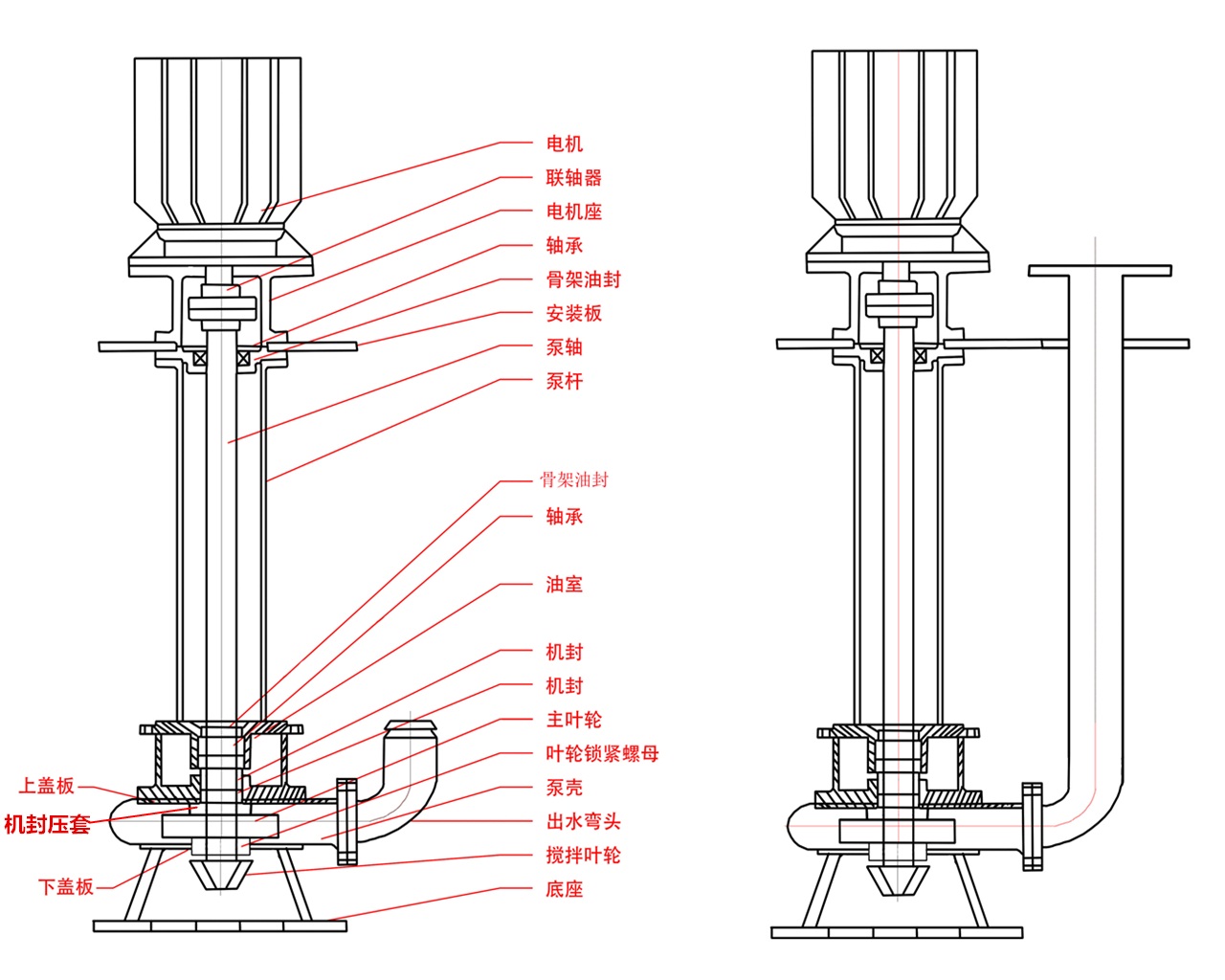

1.Haholo-holo e entsoe ka motlakase, pompo ea pompo, impeller, poleiti ea balebeli, pompo ea pompo le litiiso tse behang, joalo-joalo.

2.Pompe ea pompo, impeller le poleiti ea balebeli li entsoe ka lisebelisoa tse sa sebetseng tsa chromium alloy, tse hanyetsanang le ho senya, ho senya le lehlabathe, 'me li ka fetisa likaroloana tse kholo tse tiileng.

3.Mochine oohle ke mofuta oa pompo o omileng.Enjene e sebelisa mokhoa oa ho tiisa ka kamoreng ea oli.Ho na le lihlopha tse tharo tsa li-hard alloy mechanical lial ka hare, tse ka thibelang metsi a khatello e phahameng le litšila ho kena ka har'a lekhalo le ka hare la motlakase.

4.Ho phaella ho mokelikeli o ka sehloohong, ho boetse ho na le mokelikeli o susumetsang, o ka susumetsang sediment e behiloeng ka tlas'a metsi hore e be moferefere o phallang ebe o e ntša.

5.Mokelikeli o susumetsang o kopana ka ho toba le sebaka sa deposition, 'me mahloriso a laoloa ke botebo ba ho qoela.Ho feta moo, ka lebaka la bothata bo boholo ba lipula le ho kopana ha seaplane, sesebelisoa se thusang se ka eketsoa ho eketsa khatello ea metsi a mahareng.

6. Ha e lekanyetsoe ke mefuta e mengata ea ho hula, bokhoni bo phahameng ba slag suction, dredging ho feta

7. Thepa e sebetsa ka ho toba tlas'a metsi ntle le lerata le ho thothomela, 'me sebaka se hloekile.

Maemo a mosebetsi:

1. Ka tloaelo 380v / 50hz, matla a AC a mekhahlelo e meraro.E ka boela ea odara 50hz kapa 60hz / 230v, 415v, 660v, 1140V phepelo ea motlakase ea mekhahlelo e meraro ea AC.Bokhoni ba motlakase oa phepelo ke makhetlo a 2-3 ho feta matla a lekantsoeng a motlakase.(Hlalosa maemo a phepelo ea motlakase ha o odara)

2. Sebaka sa ho sebetsa sebakeng se bohareng ke sebaka se otlolohileng sa ho emisoa ka holimo, hape se ka kopanngoa le ho kenngoa, 'me boemo ba ho sebetsa bo tsoela pele.

3. Botebo ba basebetsi ba ho qoela: ha ho feta limithara tse 50, botebo ba bonyane ba ho qoela bo ipapisitse le enjene e qoeletseng.

4. Boima bo boholo ba likaroloana tse tiileng bohareng: 45% bakeng sa molora le 60% bakeng sa slag.

5. Mocheso o bohareng ha oa lokela ho feta 60 ℃, 'me mofuta oa R (ho hanyetsa mocheso o phahameng) ha o fete 140 ℃,' me ha o na likhase tse tukang le tse phatlohang.

Sebaka sa kopo: (ha se felle feela ho tse latelang)

1. Indasteri ea lik'hemik'hale, baeloji, matla a mocheso, ho qhibilihisa, li-ceramics, meriana, masela le liindasteri tse ling ho ntša sediment tanka le lipalangoang.

2. Setsi sa tlhoekiso ea likhoerekhoere, setsi sa tšepe le tšepe, setsi sa ho fehla matla a mocheso, mochini oa pampiri le litšila tse ling tsa tanka ea sedimentation, ho tlosoa ha lehlabathe le lehlohlojane.

3. Mashala a hlatsoang slurry, slag ea mashala, semela sa matla se fofa molora o molora, ho ntšoa ha slime ea mashala, lipalangoang.

4. Ho hloekisoa ha letamo la li-tailings, ho tsamaisoa ha lehlabathe, slag le ore slurry setsing sa ho lokisa liminerale.

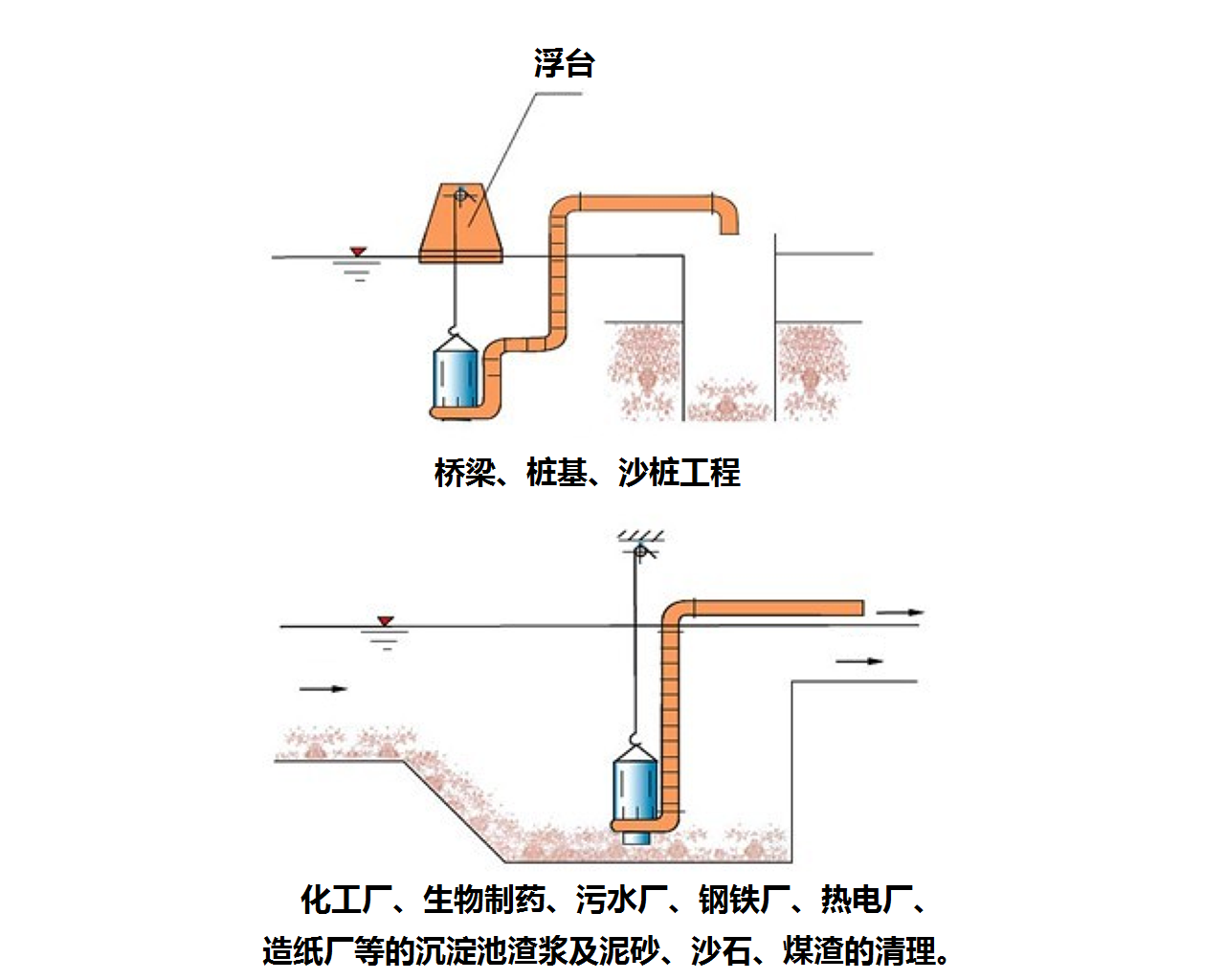

5. Ho chekoa ha liliba tse tebileng ka bophara bo boholo, liqubu tsa lehlabathe, lipeipi tsa masepala le kaho ea lipilara tsa borokho.

6. Mocheso o phahameng oa litšila slag, boiler mocheso o phahameng oa slurry, tekanyo e thibelang mocheso, metallurgy le tse ling tse phahameng tsa mocheso oa slag.

7. Phofo ea daemane, tailings ore, quartz sand ore, rare earth ore, joalo-joalo li sebelisetsoa ho ntša phofo ea ore le seretse.

8. Ho lokisoa ha lebōpo la leoatle, ho theola lehlabathe le ho lokisoa, ho boloka metsi a setsi sa motlakase le taolo ea matsoai, joalo-joalo.

9. Lipalangoang le ho tlosoa ha lisebelisoa tse sa tšoaneng tsa slurry tse kang lirafshoa le phofo ea 'mabole.

10. Phekolo ea seretse le seretse mererong ea kaho le ho baballa metsi, likhoebo tsa indasteri le tsa merafo, le boenjineri ba masepala.

11. Mokelikeli oa metsi, seretse, kaho ea masoba a qubu ea liliba tse tebang, le drainage ea drainage nakong ea kaho ea kotopo ea borokho.

12. Ho ntšoa ha litšila liphaepheng tsa masepala, liteishene tsa ho pompa metsi a pula, le liteishene tse fehlang motlakase ka metsi.

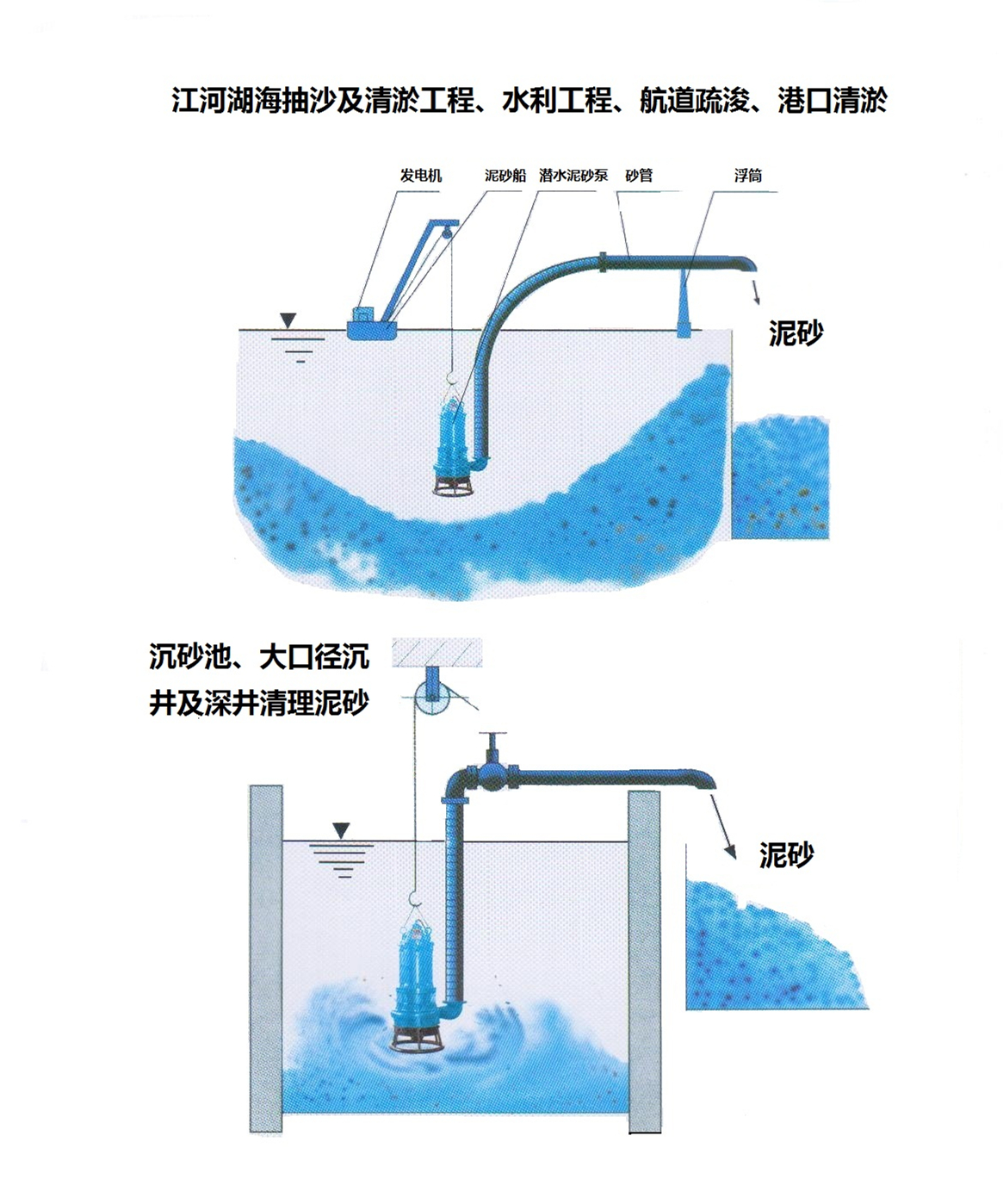

13. Merero ea ho rema lehlabathe le ho monya lehlabathe bakeng sa linōka, matša, matamo le linōka tsa litoropo.

14. Merero ea ho phunya metsi a tebileng joalo ka boema-kepe, likepe tsa likepe le likanale tsa ho sesa, le taolo ea sediment.

15. Fetisa mecha ea litaba e kang slurry e nang le karolo e kholoanyane e tiileng

Mokhoa oa ho kenya

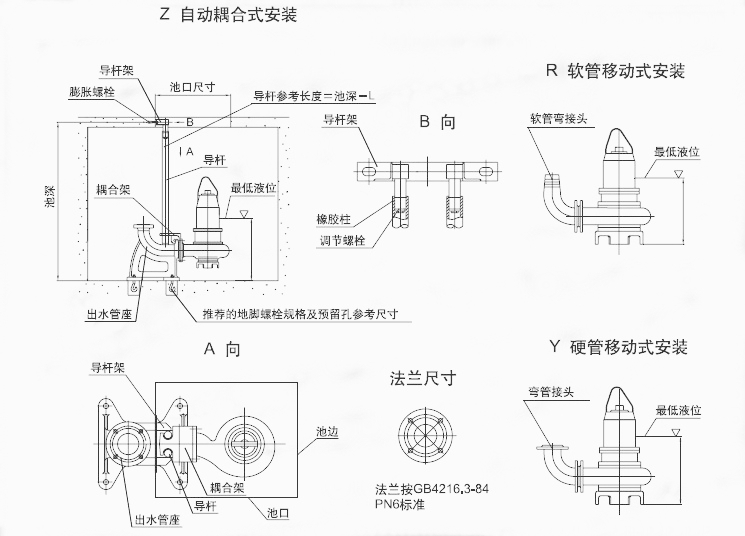

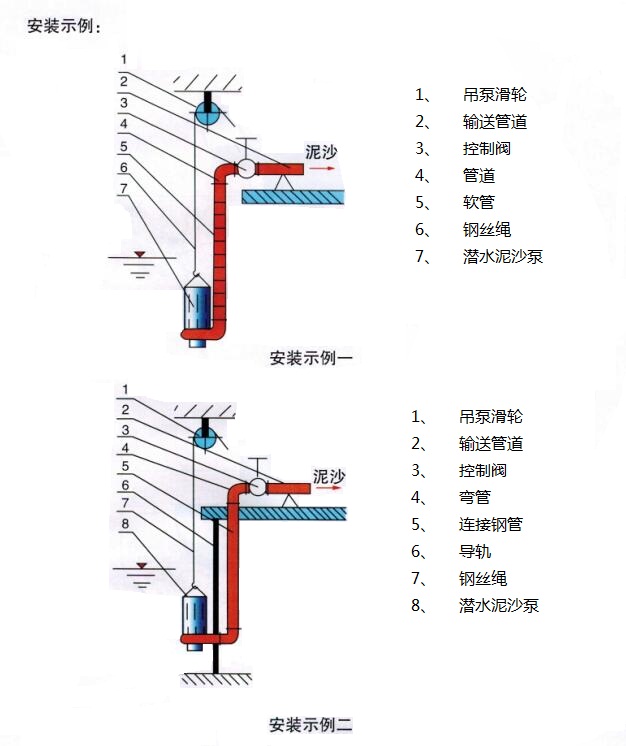

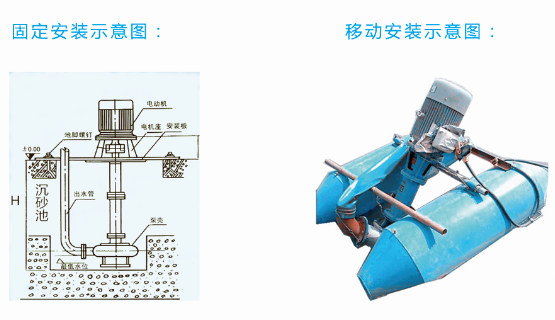

Pompo ea lehlabathe e ka tlas'a metsi e hlahisoang ke k'hamphani ea rona e na le pompo ea coaxial, sebopeho sa compact, ts'ebetso e phahameng, ho kenya le tlhokomelo e bonolo, ts'ebetso ea moruo, le ho ikamahanya le maemo ho matla.Mekhoa ea eona ea ho kenya e kenyelletsa ho kenya mohala oa selefouno le ho kenngoa ho tsitsitseng.Tlhophiso e tsitsitseng e arotsoe ka ho iketsa Coupling installing le fixed dry install, ho kenya mohala ho boetse ho bitsoa ho kenya mahala.

Mokhoa oa ho kenya mohala Pompo ea motlakase e tšehetsoa ke bracket, 'me hose ea ho ntša metsi e ka kopanngoa.E loketse bakeng sa phekolo ea linōka, ho ntša likhoerekhoere tsa indasteri, ho pompa litšila tsa kaho ea masepala le liketsahalo tse ling.

Ho kengoa ka boiketsetso ho kopanya

Sesebediswa sa othomathike sa ho kopanya se ka kenya pompo ka potlako le ha bonolo ho kenya pompo ya motlakase sebakeng sa lehlabathe ho bapa le seporo sa tataiso e thellang, mme pompo le setsi di kopanngwa ka boyona ebe di kwalwa.Ho kenya le ho hlokomela ho bonolo haholo.

Mofuteng ona oa ho kenya, pompo e kopantsoe le sesebelisoa sa ho kopanya, 'me setsi sa ho kopanya se behiloe ka tlase ho sekoti sa pompo (ha sekoti sa likhoerekhoere se hahoa, li-bolts tsa ankora li kenngoa 'me motheo oa ho kopanya o ka lokisoa ha o le teng. tshebediso).E ea holimo le tlase ka bo eona.Ha pompo e theoha, sesebelisoa sa ho kopanya se ikamahanya le setsi sa ho kopanya, 'me ha pompo e phahamisoa, e tlosoa ka bo eona ho tloha setsing sa ho kopanya.

Mokhoa ona o ka ba le li-switches tsa hydraulic, mabokose a mahareng a li-terminal le likhabinete tse ikemetseng tsa ts'ireletso ho latela litlhoko tsa mosebelisi.Khethong, mokhoa oa pompo, mokhoa oa ho kenya, botebo ba tanka, le mokhoa oa ts'ireletso oa taolo ea pompo o lokela ho bontšoa molemong oa ho fana ka sistimi e nepahetseng.Haeba basebelisi ba na le litlhoko tse khethehileng, fektheri ea rona e ka fana ka lipompo tse nang le lisebelisoa tse khethehileng.

E tsitsitseng e omileng ho kenya

Sesebelisoa sa pompo se ka lehlakoreng le leng la sekoti sa pompo 'me se tsitsitse botlaaseng hammoho le phala ea ho kenya metsi.Ka lebaka la tsamaiso ea ho futhumatsa baki ea metsi, pompo e ka tiisetsoa hore e tla sebetsa ka mojaro o feletseng.Melemo: Tšusumetso e tsoelang pele ea ho phalla ha metsi holim'a metsi ha e senye pompo 'me e ka mamella likhohola ka phoso.E loketse kaho ea 'masepala, phallo ea likhoerekhoere tse tsoang seteisheneng sa ho pompa ka tlas'a lefatše ka holim'a overpass.

Mixer ka tsela e latelang

Mixer ka tsela e latelang

Ipontsho ya ho kenya

Ipontsho ya ho kenya Apontsho ya kopo

Apontsho ya kopo

Products foto

Products foto

Lintlha tsa tšebeliso:

Lintlha tsa tšebeliso:

1. Pele o qala, hlahloba ka hloko hore na pompo ea motlakase e holofetse kapa e senyehile nakong ea lipalangoang, polokelo le ho kenya, le hore na li-fasteners li hlephile kapa li oa;

2. Sheba thapo bakeng sa tšenyo, ho robeha le liketsahalo tse ling.Haeba e senyehile, e tlameha ho nkeloa sebaka ho qoba ho lutla;

3. Sheba hore na motlakase o bolokehile ebile o tšepahala.Voltage e lekantsoeng e tlameha ho lumellana le nameplate.

4. Sebelisa megohmmeter ho hlahloba mocheso oa mocheso o batang oa stator winding ea motor ha oa lokela ho ba ka tlase ho 50MΩ;

5. Ho thibetsoe ka ho feletseng ho sebelisa mohala oa pompo e le thapo ea ho kenya le ho phahamisa ho qoba kotsi;

6. Tsela ea ho potoloha ea pompo e khahlanong le oache ha e shejoa ho tsoa ho metsi.Haeba e khutlisetsoa morao, lithapo tse peli tse ka har'a thapo li tlameha ho khutlisoa bakeng sa boemo ba khokahano, 'me pompo e ka potoloha pele.

7. Pompo e lokela ho qoelisoa ka metsing ho ea holimo.Ha ea lokela ho behoa ka tsela e tšekaletseng kapa e qabeletsoe ka har'a seretse.Ha pompo e fetisoa, matla a tlameha ho khaoloa.

8. Pele pompo ea motlakase e emisoa, e tlameha ho kenngoa metsing a hloekileng metsotso e 'maloa ho thibela sediment ho tloha pompong le ho netefatsa hore pompo ea motlakase e hloekile;

9. Ha pompo ea motlakase e sa sebelisoe ka nako e telele, e lokela ho ntšoa ka metsing ho fokotsa monyetla oa ho senya stator winding ea motlakase le ho eketsa bophelo ba tšebeletso ea pompo ea motlakase;

10. Tlas'a maemo a tloaelehileng a ts'ebetso, ka mor'a hore pompo ea motlakase e sebetse halofo ea selemo (e ka tsoela pele ho fihlela likhoeli tse tharo haeba matla a mosebetsi a le maholo), tlhokomelo e lokela ho etsoa, likarolo tse apereng le tse apereng li lokela ho nkeloa sebaka, boemo ba ho tiisa. e lokela ho hlahlojoa, 'me mafura a nang le mafura a lokela ho tlatsoa kapa a nkeloe sebaka.Le ho kenya oli ka kamoreng ea oli ho netefatsa ts'ebetso e ntle ea pompo ea motlakase;

11. Ha botebo ba metsi bo feta limithara tse 20, ho khothaletsoa hore likhoele li tlameletsoe ka liphaphatha ka nako ea mithara e le 'ngoe.Ha pompo ea metsi e sebetsa, likhoele lia robeha.Ha metsi a tsamaisoa libakeng tse telele, liphaephe tsa metsi li tlameletsoe ka liphaphatha sebakeng sa limithara tse 5 ho thusa ho tsamaea.

Ftharollo le tharollo:

| Failure | Ho ka etsahalalebaka | Stlhophiso |

| Boemo bo phahameng bo feta ba nako e reriloeng | 1.Pompo e na le khanyetso ea ho senya | 1. Fetola lekhalo |

| 2. Hlooho ea sesebelisoa e tlaase haholo, 'me pompo e matha ka lebelo le leholo la phallo. | 2.The valve e laola phallo kapa e nkela sebaka se loketseng pompo ea hlooho | |

| 3.Ho jara tšenyo | 3.Fetola libering | |

| Enjene e etsa lerata le makatsang nakong ea ho qala2. Sheba potoloho 'me u kopanye ho khaola | 1.The voltage e tlase haholo | 1.Lokisa motlakase ho boleng bo lekantsoeng |

| 2.Mohato o le mong oa ts'ebetso ea motlakase | 2. Sheba potoloho 'me u kopanye ho khaola | |

| 3, taba e tsoang kantle e khomaretsoe pompong | 3.Tlosa mebele esele | |

| 4, impeller le sekoaelo sa pompo se ka hare kapa poleiti e monyang | 4.Lokisa tumello ea impeller ho boleng bo tloaelehileng | |

| Che kapa metsi a manyane | 1, impeller reverse | 1.Fetola thapo efe kapa efe ea mekhahlelo e 'meli |

| 2.Sefahla sa metsi se koetsoe | 2.Hlakola tšitiso | |

| 3.Sekena sa metsi se tsoa ka metsing | 3. Theola boemo ba pompo hore e kene ka tlas'a metsi | |

| 4. Ho lutla kapa ho thiba ha pipe ea metsi | 4.Ho fetola lipeipi tsa metsi kapa u tlose litšila | |

| 5.Hlooho ea sebele e phahame haholo | 5.Khetha pompo e nang le hlooho e loketseng | |

| Insulation resistance e theoha ka tlase ho 0.5MΩ | 1.Sehokelo sa cable se senyehile | 1.Reprocess sehokedi sa thapo |

| 2. Tšenyo ea insulation ea stator winding | 2.Fetola sebaka sa stator winding | |

| 3.Metsi ka sekoting sa motlakase | 3. Kenyelletsa mongobo le windings e omileng | |

| 4.Thapo e senyehile | 4.Ho lokisa likhoele | |

| Ho matha ho sa tsitsang le ho thothomela ho matla | 1.Impeller e apere haholo | 1,nkela sebaka sa impeller |

| 2. Lithako tse khomaretsoeng likarolong tse bilikang | 2,hlakisa lintho tse khomaretsoeng | |

| 3.Ho jara tšenyo | 3,fetola dibering |

ZNQ, ZNQX,ZNQL, ZNQR, ZNQRX lintlha tsa tekheniki (feela bakeng sa referense)

| Che. | Model | Fsekhahla se tlase M3/h | Head m | Diameter mm | Petsoe kw | Granularitymm |

| 50ZNQ15-25-3 | 15 | 25 | 50 | 3 | 10 | |

| 50ZNQ30-15-3 | 30 | 15 | 50 | 15 | ||

| 50ZNQ40-13-3 | 40 | 13 | 50 | 15 | ||

| 80ZNQ50-10-3 | 50 | 10 | 80 | 20 | ||

| 50ZNQ24-20-4 | 24 | 20 | 50 | 4 | 20 | |

| 50ZNQ40-15-4 | 40 | 15 | 50 | 20 | ||

| 80ZNQ60-13-4 | 60 | 13 | 80 | 20 | ||

| 50ZNQ25-30-5.5 | 25 | 30 | 50 | 5.5 | 18 | |

| 80ZNQ30-22-5.5 | 30 | 22 | 80 | 20 | ||

| 100ZNQ65-15-5.5 | 65 | 15 | 100 | 25 | ||

| 100ZNQ70-12-5.5 | 70 | 12 | 100 | 25 | ||

| 80ZNQ30-30-7.5 | 30 | 30 | 80 | 7.5 | 25 | |

| 80ZNQ50-22-7.5 | 50 | 22 | 80 | 25 | ||

| 100ZNQ80-12-7.5 | 80 | 12 | 100 | 30 | ||

| 100ZNQ100-10-7.5 | 100 | 10 | 100 | 30 | ||

| 80ZNQ50-26-11 | 50 | 26 | 80 | 11 | 26 | |

| 100ZNQ80-22-11 | 80 | 22 | 100 | 30 | ||

| 100ZNQ130-15-11 | 130 | 15 | 100 | 35 | ||

| 100ZNQ50-40-15 | 50 | 40 | 100 | 15 | 30 | |

| 100ZNQ60-35-15 | 60 | 35 | 100 | 30 | ||

| 100ZNQ100-28-15 | 100 | 28 | 100 | 35 | ||

| 100ZNQ130-20-15 | 130 | 20 | 100 | 37 | ||

| 150ZNQ150-15-15 | 150 | 15 | 150 | 40 | ||

| 150ZNQ200-10-15 | 200 | 10 | 150 | 40 | ||

| 100ZNQ70-40-18.5 | 70 | 40 | 100 | 18.5 | 35 | |

| 150ZNQ180-15-18.5 | 180 | 15 | 150 | 40 | ||

| 100ZNQ60-50-22 | 60 | 50 | 100 | 22 | 28 | |

| 100ZNQ100-40-22 | 100 | 40 | 100 | 30 | ||

| 150ZNQ130-30-22 | 130 | 30 | 150 | 32 | ||

| 150ZNQ150-22-22 | 150 | 22 | 150 | 40 | ||

| 150ZNQ200-15-22 | 200 | 15 | 150 | 40 | ||

| 200ZNQ240-10-22 | 240 | 10 | 200 | 42 | ||

| 100ZNQ80-46-30 | 80 | 46 | 100 | 30 | 30 | |

| 100ZNQ120-38-30 | 120 | 38 | 100 | 35 | ||

| 100ZNQ130-35-30 | 130 | 35 | 100 | 37 | ||

| 150ZNQ240-20-30 | 240 | 20 | 150 | 40 | ||

| 200ZNQ300-15-30 | 300 | 15 | 200 | 50 | ||

| 100ZNQ100-50-37 | 100 | 50 | 100 | 37 | 30 | |

| 150ZNQ150-40-37 | 150 | 40 | 150 | 40 | ||

| 200ZNQ300-20-37 | 300 | 20 | 200 | 50 | ||

| 200ZNQ400-15-37 | 400 | 15 | 200 | 50 | ||

| 150ZNQ150-45-45 | 150 | 45 | 150 | 45 | 40 | |

| 150ZNQ200-30-45 | 200 | 30 | 150 | 42 | ||

| 200ZNQ350-20-45 | 350 | 20 | 200 | 50 | ||

| 200ZNQ500-15-45 | 500 | 15 | 200 | 50 | ||

| 150ZNQ150-50-55 | 150 | 50 | 150 | 55 | 40 | |

| 150ZNQ250-35-55 | 250 | 35 | 150 | 42 | ||

| 200ZNQ300-25-55 | 300 | 25 | 200 | 50 | ||

| 200ZNQ400-20-55 | 400 | 20 | 200 | |||

| 250ZNQ600-15-55 | 600 | 15 | 250 | 50 | ||

| 100ZNQ140-60-75 | 140 | 60 | 100 | 75 | 40 | |

| 150ZNQ200-50-75 | 200 | 50 | 150 | 45 | ||

| 150ZNQ240-45-75 | 240 | 45 | 150 | 45 | ||

| 200ZNQ350-35-75 | 350 | 35 | 200 | 50 | ||

| 200ZNQ380-30-75 | 380 | 30 | 200 | 50 | ||

| 200ZNQ400-25-75 | 400 | 25 | 200 | 50 | ||

| 200ZNQ500-20-75 | 500 | 20 | 200 | 50 | ||

| 150ZNQ250-50-90 | 250 | 50 | 150 | 90 | 44 | |

| 200ZNQ400-40-90 | 400 | 40 | 200 | 50 | ||

| 250ZNQ550-25-90 | 550 | 25 | 200 | 90 | 50 | |

| 250ZNQ400-50-110 | 400 | 50 | 250 | 110 | 50 | |

| 300ZNQ600-35-110 | 600 | 35 | 300 | 50 | ||

| 300ZNQ660-30-110 | 660 | 30 | 300 | 50 | ||

| 300ZNQ800-22-110 | 800 | 22 | 300 | 50 | ||

| 250ZNQ500-45-132 | 500 | 45 | 250 | 132 | 50 | |

| 300ZNQ700-35-132 | 700 | 35 | 300 | 50 | ||

| 300ZNQ800-30-132 | 800 | 30 | 300 | 50 | ||

| 300ZNQ1000-22-132 | 1000 | 22 | 300 | 50 |

Tlhokomeliso: Paramethara ena ke ea litšupiso, ka kopo hlalosa ha o laela: phallo, hlooho, matla, caliber le likarolo tse ling, ho itšetlehile ka konteraka.

Peipi e pompang rabara e manganga lehlabatheng

Boholo ba phala ea rabara

50mm, 65mm, 80mm, 100mm, 150mm, 200mm, 250mm, 300mm, 350mm, 400mm等.

botenya: 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm ho feta.

Tlas'a khatello: 2, 3, 4, 6, 8, 10kg

Lipheletso ka bobeli tsa phala li ka hlomelloa ka li-flange tse tšoanang bakeng sa ho hokahanya habonolo.

Mofuta oa pompo ea seretse e otlolohileng ea ZNL

Selelekela sa sehlahisoa:

Pompo ea seretse e otlolohileng ea ZNL e entsoe haholo ka casing ea pompo, impeller, setsi sa pompo, setsi sa makoloi le enjene.Pompe ea pompo, impeller le poleiti ea balebeli li entsoe ka alloy e manganga, e nang le matla a phahameng, ho hanyetsa ho apara, ho feta hantle le ho sebetsa hantle haholo.E ka sebelisoa ka mokhoa o otlolohileng kapa oblique, ka sebaka se senyenyane sa maoto.Sekoahelo sa pompo se hloka ho patoa bohareng ho sebetsa, 'me ho bonolo ho qala ntle le kenyelletso ea metsi.Ho na le litlhaloso tse fapaneng tsa bolelele ba switchboard, e le hore mosebelisi a ka khetha yuniti ho latela morero.

Haholo-holo e sebelisoa ts'ireletso ea tikoloho, boenjiniere ba masepala, litsi tsa motlakase tse futhumatsang mocheso, limela tsa ho pheha khase, lihlahisoa tsa oli, litšilo tsa tšepe, merafo, ho etsa pampiri, limela tsa samente, limela tsa lijo, indasteri ea khatiso le ho daea ho pompa lino tse teteaneng, oli e boima, masala a oli le litšila. liquid , Sludge, seretse, quicksand, le seretse se tsamaeang se tsoang likanaleng tsa likhoerekhoere tsa litoropo, hammoho le maro le maro a senyang a nang le matsoai.

Tlhaloso ea mohlala:

100 ZNL(X)100-28-15

100 - bophara bo tloaelehileng ba boema-kepe ba ho ntša pompo (mm)

ZNL – pompo ea seretse e otlolohileng

(X) -tšepe e sa hloekang

100 - phallo e lekantsoeng (m3/h)

28 -hlooho e lekantsoeng (m)

15 - matla a lekantsoeng a motlakase (Kw)

Molemo oa lihlahisoa :

1. Pompo e tiisitsoe ka lihlopha tse 2 tsa litiiso tsa mechine tse thata tsa alloy;

2. Mokelikeli o thusang o sebelisetsoa ho fokotsa khatello ea mokokotlo oa mokokotlo le ho lelefatsa bophelo ba tiiso;

3. Likarolo tsa morao-rao li entsoe ka alloy e hanyetsanang le chromium le lisebelisoa tse ling ho hanela abrasion;

4. Ho phaella ho mokelikeli o ka sehloohong, ho na le mokelikeli o susumetsang, o ka susumetsang sediment e behiloeng ka tlas'a metsi hore e be moferefere o phallang ebe o e ntša;

5. Mokelikeli o susumetsang o haufi ka ho toba le sebaka sa deposition, se nang le mahloriso a phahameng le bokhoni bo phahameng.

sebelisa:

1. Ho hloekisoa ha setsi sa lik'hemik'hale, ho qhibilihisa tšepe, tanka ea sedimentation ea tšepe ea tšepe, letangoana la sedimentation la setsi sa motlakase, letamo la sedimentation la semela sa likhoerekhoere.

2. Ho tlosoa ha litšila, seretse, lipeipi tsa masepala, le kaho ea seteishene sa ho pompa metsi a pula.

3. Hlakola mefuta eohle ea silicon carbide, lehlabathe la quartz, slag ea tšepe le li-slag tse tiileng tsa metsi.

4. Fofisa lipalangoang tsa molora, seretse le mashala sebakeng sa motlakase.

5. Lipalangoang tsa mehatla, li-tailings ore tse fapaneng, slurry, ore slurry, mashala a mashala, slag, kalafo ea slag, joalo-joalo.

6. Ho etsa lehlabathe, ho roala tšepe, ho potlaka ha khauta, ho ntšoa ha lehlabathe la tšepe le ho tsamaisa thepa ea seretse e nang le li-slags tse fapaneng.

7. Lisebelisoa tsa lipalangoang tse kang lehlabathe, seretse sa tšepe, seretse sa mashala, lehlabathe le lehlohlojane tse nang le likaroloana tse kholoanyane tse tiileng.

8. Haeba e sebelisana le pompo ea metsi e nang le khatello e phahameng ho theha yuniti ea boenjiniere ba hydraulic mechanized, e ka sebelisoa bakeng sa mesebetsi ea ho phunya linokeng tsa litoropong, libakeng tse lebopong la leoatle, likoung, matšeng, matamo, joalo-joalo.

'Mapa oa' mele le sebopeho sa pompo ea seretse e otlolohileng

Pkopano ea ump

Pkopano ea ump

Userkopano :

Userkopano :

Mohlala oa ZNL, ZNLX (feela bakeng sa litšupiso)

Mohlala oa ZNL, ZNLX (feela bakeng sa litšupiso)

| Che. | Model | Fsekhahla se tlase M3/h | Head m | Diameter mm | matla kw | Granularitymm |

| 1 | 50ZNL15-25-3 | 15 | 25 | 50 | 3 | 10 |

| 2 | 50ZNL30-15-3 | 30 | 15 | 50 | 15 | |

| 3 | 50ZNL40-13-3 | 40 | 13 | 50 | 15 | |

| 4 | 80ZNL50-10-3 | 50 | 10 | 80 | 20 | |

| 5 | 50ZNL24-20-4 | 24 | 20 | 50 | 4 | 20 |

| 6 | 50ZNL40-15-4 | 40 | 15 | 50 | 20 | |

| 7 | 80ZNL60-13-4 | 60 | 13 | 80 | 20 | |

| 8 | 50ZNL25-30-5.5 | 25 | 30 | 50 | 5.5 | 18 |

| 9 | 80ZNL30-22-5.5 | 30 | 22 | 80 | 20 | |

| 10 | 100ZNL65-15-5.5 | 65 | 15 | 100 | 25 | |

| 11 | 100ZNL70-12-5.5 | 70 | 12 | 100 | 25 | |

| 12 | 80ZNL30-30-7.5 | 30 | 30 | 80 | 7.5 | 25 |

| 13 | 80ZNL50-22-7.5 | 50 | 22 | 80 | 25 | |

| 14 | 100ZNL80-12-7.5 | 80 | 12 | 100 | 30 | |

| 15 | 100ZNL100-10-7.5 | 100 | 10 | 100 | 30 | |

| 16 | 80ZNL50-26-11 | 50 | 26 | 80 | 11 | 26 |

| 17 | 100ZNL80-22-11 | 80 | 22 | 100 | 30 | |

| 18 | 100ZNL130-15-11 | 130 | 15 | 100 | 35 | |

| 19 | 100ZNL50-40-15 | 50 | 40 | 100 | 15 | 30 |

| 20 | 100ZNL60-35-15 | 60 | 35 | 100 | 30 | |

| 21 | 100ZNL100-28-15 | 100 | 28 | 100 | 35 | |

| 22 | 100ZNL130-20-15 | 130 | 20 | 100 | 37 | |

| 23 | 150ZNL150-15-15 | 150 | 15 | 150 | 40 | |

| 24 | 150ZNL200-10-15 | 200 | 10 | 150 | 40 | |

| 25 | 100ZNL70-40-18.5 | 70 | 40 | 100 | 18.5 | 35 |

| 26 | 150ZNL180-15-18.5 | 180 | 15 | 150 | 40 | |

| 27 | 100ZNL60-50-22 | 60 | 50 | 100 | 22 | 28 |

| 28 | 100ZNL100-40-22 | 100 | 40 | 100 | 30 | |

| 29 | 150ZNL130-30-22 | 130 | 30 | 150 | 32 | |

| 30 | 150ZNL150-22-22 | 150 | 22 | 150 | 40 | |

| 31 | 150ZNL200-15-22 | 200 | 15 | 150 | 40 | |

| 32 | 200ZNL240-10-22 | 240 | 10 | 200 | 42 | |

| 33 | 100ZNL80-46-30 | 80 | 46 | 100 | 30 | 30 |

| 34 | 100ZNL120-38-30 | 120 | 38 | 100 | 35 | |

| 35 | 100ZNL130-35-30 | 130 | 35 | 100 | 37 | |

| 36 | 150ZNL240-20-30 | 240 | 20 | 150 | 40 | |

| 37 | 200ZNL300-15-30 | 300 | 15 | 200 | 50 | |

| 38 | 100ZNL100-50-37 | 100 | 50 | 100 | 37 | 30 |

| 39 | 150ZNL150-40-37 | 150 | 40 | 150 | 40 | |

| 40 | 200ZNL300-20-37 | 300 | 20 | 200 | 50 | |

| 41 | 200ZNL400-15-37 | 400 | 15 | 200 | 50 | |

| 42 | 150ZNL150-45-45 | 150 | 45 | 150 | 45 | 40 |

| 43 | 150ZNL200-30-45 | 200 | 30 | 150 | 42 | |

| 44 | 200ZNL350-20-45 | 350 | 20 | 200 | 50 | |

| 45 | 200ZNL500-15-45 | 500 | 15 | 200 | 50 | |

| 46 | 150ZNL150-50-55 | 150 | 50 | 150 | 55 | 40 |

| 47 | 150ZNL250-35-55 | 250 | 35 | 150 | 42 | |

| 48 | 200ZNL300-24-55 | 300 | 24 | 200 | 50 | |

| 49 | 250ZNL600-15-55 | 600 | 15 | 250 | 50 | |

| 50 | 100ZNL140-60-75 | 140 | 60 | 100 | 75 | 40 |

| 51 | 150ZNL200-50-75 | 200 | 50 | 150 | 45 | |

| 52 | 150ZNL240-45-75 | 240 | 45 | 150 | 45 | |

| 53 | 200ZNL350-35-75 | 350 | 35 | 200 | 50 | |

| 54 | 200ZNL380-30-75 | 380 | 30 | 200 | 50 | |

| 55 | 200ZNL400-25-75 | 400 | 25 | 200 | 50 | |

| 56 | 200ZNL500-20-75 | 500 | 20 | 200 | 50 | |

| 57 | 250ZNL400-50-110 | 400 | 50 | 250 | 110 | 50 |

| 58 | 300ZNL600-35-110 | 600 | 35 | 300 | 50 | |

| 59 | 300ZNL660-30-110 | 660 | 30 | 300 | 50 | |

| 60 | 300ZNL800-22-110 | 800 | 22 | 300 | 50 | |

| 61 | 250ZNL500-45-132 | 500 | 45 | 250 | 132 | 50 |

| 62 | 300ZNL700-35-132 | 700 | 35 | 300 | 50 | |

| 63 | 300ZNL800-30-132 | 800 | 30 | 300 | 50 |

Ho kgothaletswa ho reka koloi e tloaelehileng ea naha, 'me motlakase o sa tloaelehang oa naha o khothalletsoa ho reka mochine o moholoanyane oa mohlala.Sebopeho sa ka hare: Ke bakeng sa boitsebiso feela, 'me sehlahisoa sa sebele se tla rena.Haeba ho na le karolo efe kapa efe ea sebopeho e ntlafalitsoeng le ho ntlafatsoa, ntle le tsebiso.

Boleng le ka mor'a thekiso

1. Litekanyetso tsa boleng le botekgeniki: E entsoe ho latela maemo a naha a CJ / T3038-1995, mme sistimi ea netefatso ea boleng e sebelisoa ho latela ISO9001.

2. Maemo a Setegeniki, Maemo le Nako ea Boikarabello ba Bafani ba Boleng: Litiisetso tse Tharo tsa Boleng Ntle le Likarolo Tse Kotsing.

3. Nakong ea tiisetso;tlas'a boemo ba hore mochine o tsamaisang thepa o finyella litlhoko tsa likarolo tse fetang tsa pompo 'me o ka lumellana le bukana ea litaelo, ha sehlahisoa se senyehile ka lebaka la tlhahiso e fokolang kapa e sa khone ho sebetsa ka mokhoa o tloaelehileng, fektheri e tla e nkela sebaka kapa e e lokise mahala, le ho roala. likarolo ha li mona lentsoe.

Ntlha ea bone, fektheri e netefatsa phepelo e tlaase ea nako e telele ea lisebelisoa bakeng sa bareki.

Ea bohlano, bakeng sa yuniti ea tšebelisano-'moho, fektheri e fana ka tšebeletso ea ka mor'a thekiso ho bareki ka ho feletseng.

Tse tšeletseng, maemo a khethehileng, ka kopo hlalosa ha o laela, e le hore a se ke a ama ka mor'a thekiso.

Tsebiso ea taelo :

1. Ka kopo, bonts'a lintlha tsa sehlahisoa le mefuta ea ho odara ha o odara;

2. Li-impellers, li-impellers, lipoleiti tse ka holimo le tse tlaase tsa balebeli, litiiso tsa mechine le likarolo tse ling tse roaloang li ka rekoa ka thoko bakeng sa tšebeliso ea tšohanyetso ho latela litlhoko;

3. Haeba sesebelisoa sa mosebelisi se sa kopane le maemo a ts'ebeliso, joalo ka voltage, frequency, kapa boleng ba metsi, mosebelisi a ka kopa liodara tse khethehileng.